Research

- English

- Türkçe

An Overview of Our Research

In the Nanomechanics Lab, we focus on the development and mechanical characterization of additively manufactured materials and structures. We investigate a wide range of engineering materials including nanostructured metals, metallic glasses, high entropy alloys, hard coatings, and polymer composites.

Additive Manufacturing (Metals)

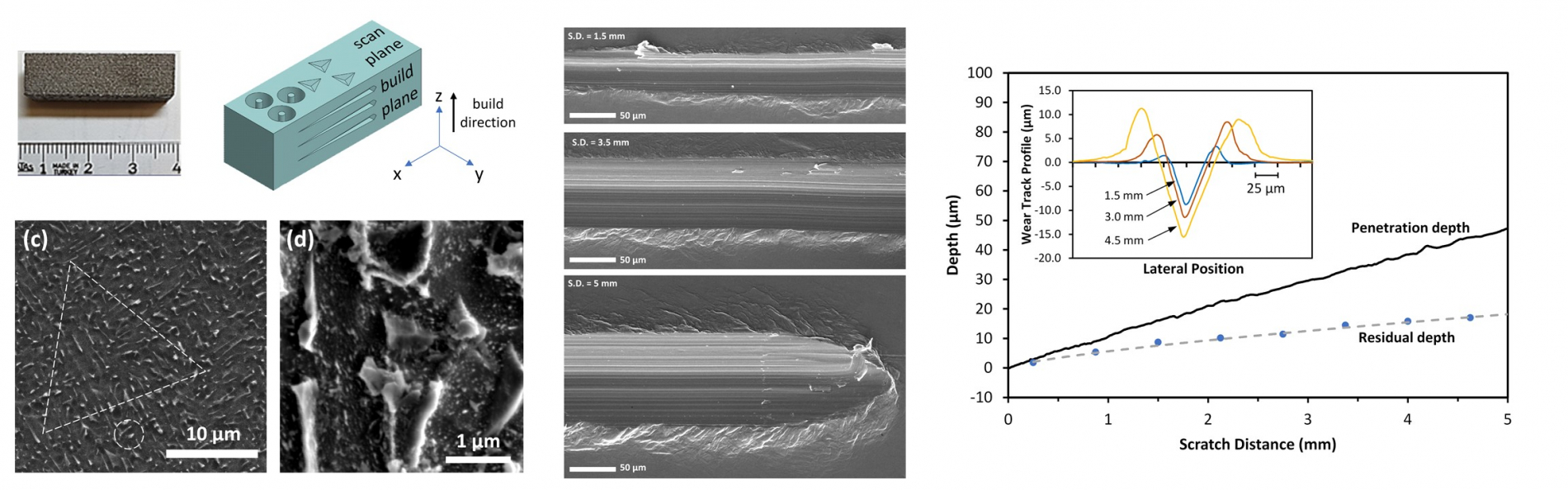

Understanding the mechanical performance of printed parts is critical for the reliable usage of these components in engineering applications. For metal AM, we focus on understanding the mechanics of the printed parts at the small scale. Such investigation help us understand the large-scale mechanical behavior of AM-produced materials and structures.

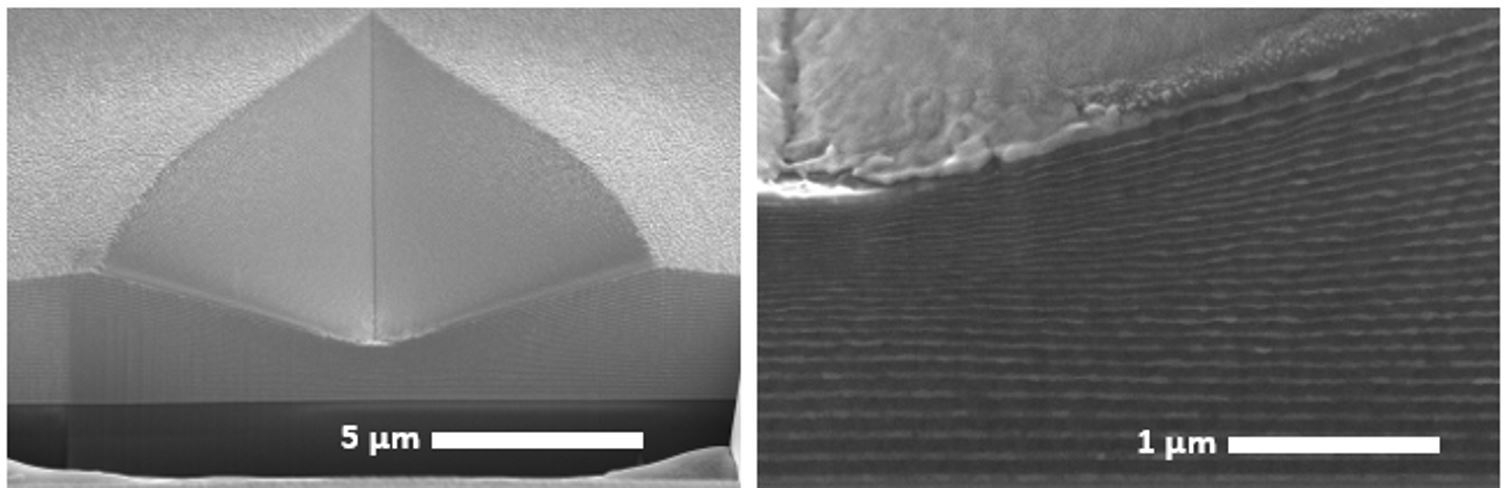

A summary of microstructural and micromechanical characterization performed on Ti6Al4V produced by electron beam melting [1].

Additive Manufacturing (Polymers)

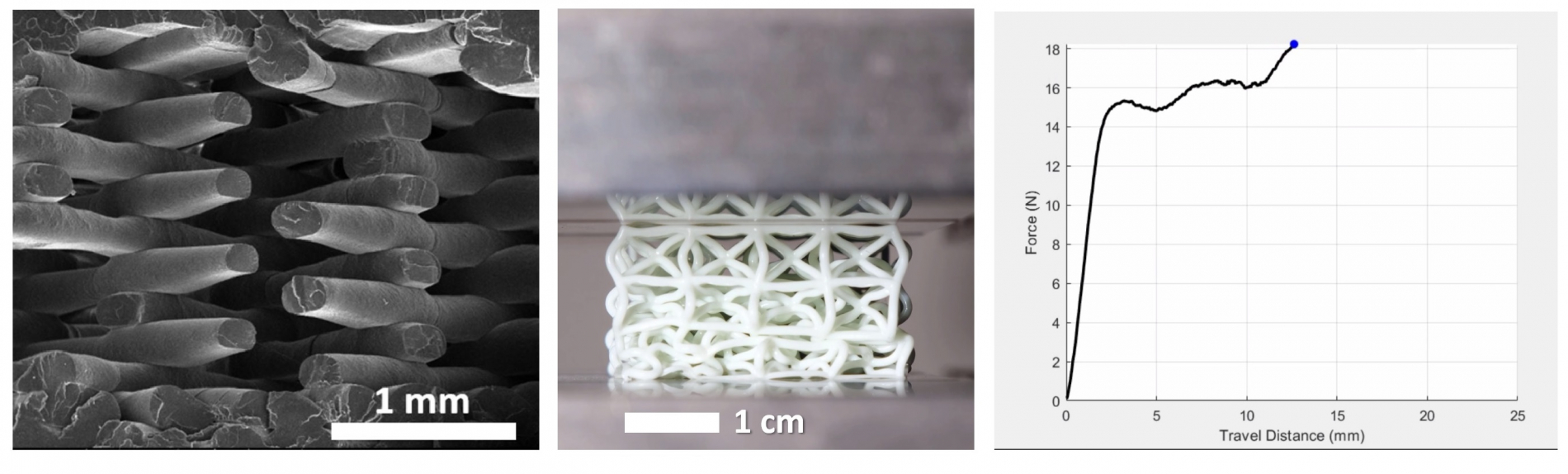

In the AM of polymers, our focus is on novel thermoplastic materials for fused filament fabrication and the mechanical behavior of parts and structures produced by these materials.

Image on the left: Electron microscopy image of the fracture surface of a 3D-printed specimen [2]. Images in the middle and on the right: Compression behavior and stress-strain data of a lattice structure produced by Digital Light Synthesis [3].

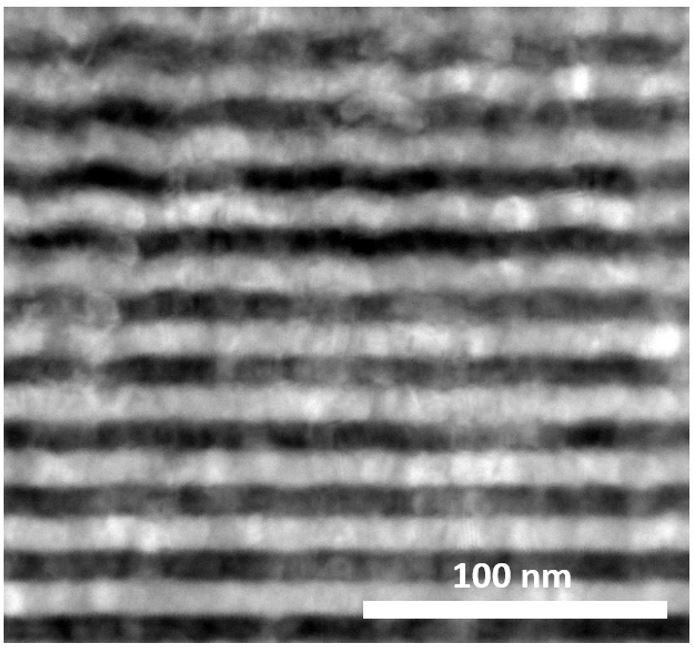

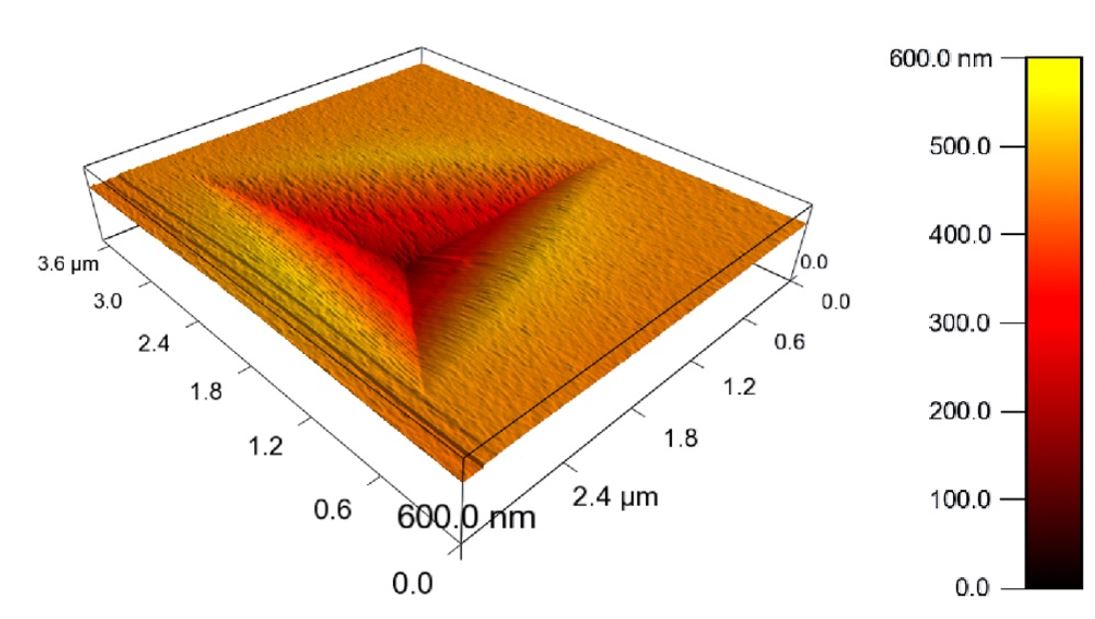

Nanostructured Metals

Nanostructured metals are promising materials for engineering applications due to their high strength, thermal stability and radiation resistance. Our research aims to understand the mechanical behavior of these materials and determine the relationship between their microstructure and mechanical properties.

Transmission electron microscopy image of nanolayered Cu-Nb [1].

Atomic force microscopy image of a nanoindent on a nanocrystalline Cu alloy [2].

Cross section image of an indent on a nanolayered metal that shows the deformation geometry [3].

Metallic Glasses and High Entropy Alloys

Metallic glasses provide outstanding strength and elastic limits. Metallic glasses' brittle nature limits their use in applications. We seek to better understand the fracture behavior of metallic glasses and develop metallic glass matrix nanocomposites with improved ductility.

High entropy alloys are new generation structural materials that offer a great design space for the development of next generation high-performance materials. Our aim in this field is to generate nanostructured HEAs and their composites with tuned properties.

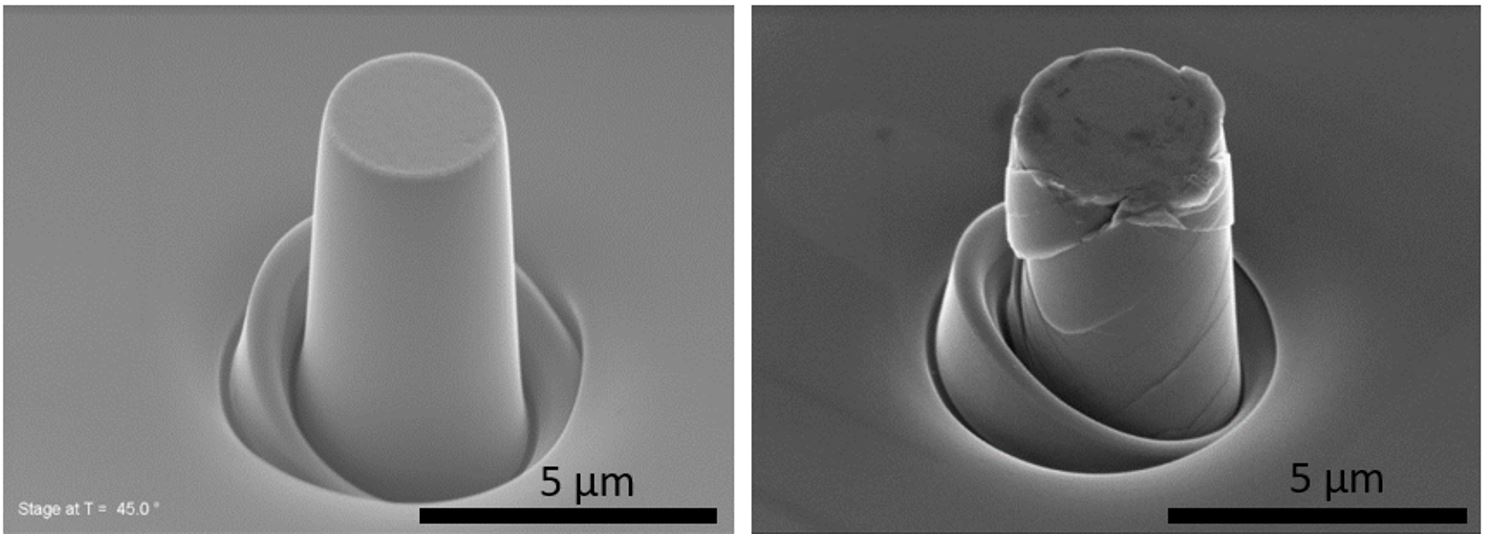

Images of a metallic glass micropillar before and after compression testing [7].

Wear Resistant Coatings

Nanostructured coatings can provide enhanced hardness, wear and scratch resistant combined with good resistance to fracture. We investigate the mechanical performance of new generation metal nitride coatings as well as promising model structures such as nanolayered metallic glass – crystalline composite coatings.

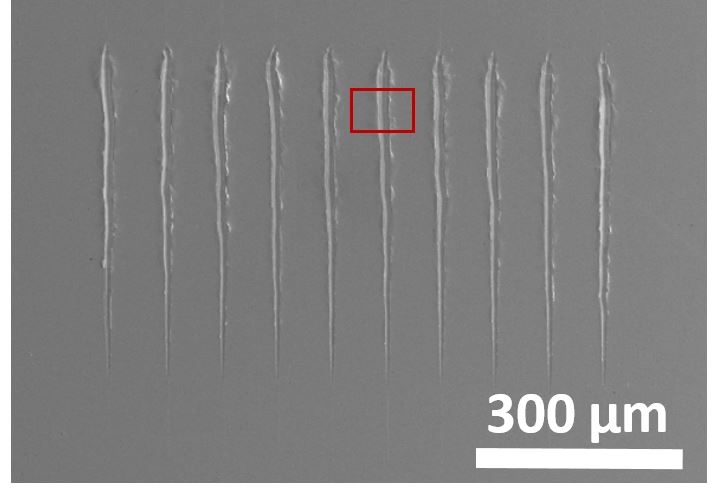

Nanoscratch measurements on nanolayered metallic glass – nanocrystalline metal composite coatings [8].

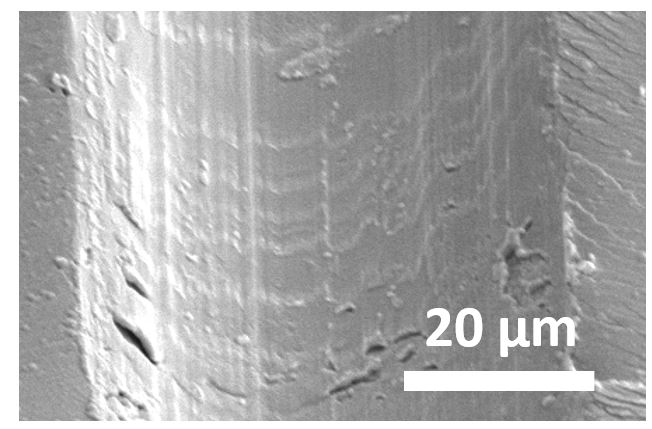

Surface morphology of a metallic glass coating upon scratch testing [8].

Polymer Composites

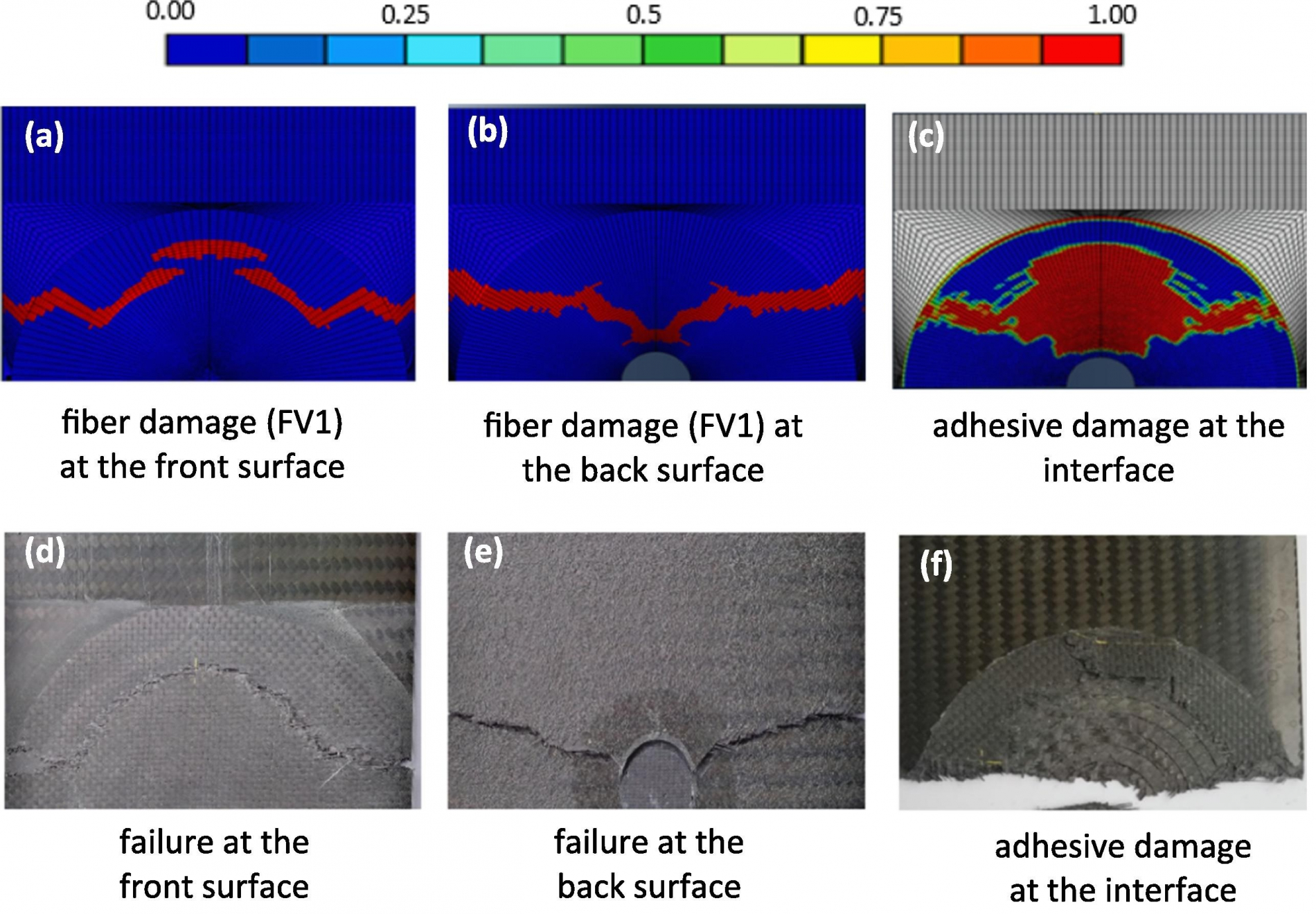

Composite materials are widely used in aerospace industry. However, their repair is still challenging and the mechanical performance of repaired structures is still not well understood. Our research aims to combine experimentation and simulations to identify the optimum repair conditions for achieving the highest load bearing capacity.

Experiment and simulation results on the fracture of a repaired carbon fiber reinforce composite [9].

References

[1] S. Özerinç, B. Kaygusuz, M. Kaş, A. Motallebzadeh, Ş. Nesli, Ö. Duygulu, O. Yılmaz, Micromechanical Characterization of Additively Manufactured Ti–6Al–4V Parts Produced by Electron Beam Melting, JOM, 73 3021–3033 (2021).

[2] B. Kaygusuz, S. Özerinç, 3 Boyutlu Yazıcı ile Üretilen PLA Bazlı Yapıların Mekanik Özelliklerinin İncelenmesi, Makina Tasarım ve İmalat Dergisi, 16 1-6 (2018).

[3] R. Neshani, D.J. McGregor, S. Tawfick, W.P. King, S. Özerinç, Mechanical Characterization of Elastomeric Lattice Parts Produced by Continuous Liquid Interface Production (Digital Light Synthesis), MRS Fall Meeting & Exhibit, 2021, Boston, USA.

[4] S. Özerinç, N. Verma, R.S. Averback, Strengthening in multilayered Cu-Nb through alloying, MRS Fall Meeting & Exhibit, 2017, Boston, USA.

[5] S. Özerinç, K. Tai, N.Q. Vo, R.S. Averback, P. Bellon, S. Dillon, W.P. King, Grain boundary strengthening in dilute nanocrystalline Cu alloys, MRS Fall Meeting & Exhibit, 2011, Boston, USA.

[6] S. Özerinç, unpublished work.

[7] F. Sıkan, S.E. Atabay, A. Motallebzadeh, S. Özerinç, İ. Kalay, E. Kalay; Effect of Sm on Thermal and Mechanical Properties of Cu-Zr-Al Bulk Metallic Glasses, Materials Science & Engineering A, 743, 168-174 (2019).

[8] M. Abboud, A. Motallebzadeh, N. Verma, S. Özerinç, Nanoscratch behavior of metallic glass-crystalline nanolayered composites, JOM, 71, 593–601 (2019).

[9] E. Sonat, M. Bakır, S. Özerinç, Failure Behavior of On-Site Repaired CFRP Laminates, Composite Structures, 311, 116806 (2023).